Scientist Polytechnic University A. A. TRINCHENKO improved method of vortex combustion, whereby the amount of harmful substances in the production process of electric energy at thermal power plants decreases to 70%, and financial benefits from implementation of the technology is estimated at tens of millions of rubles a year.

This development was highly appreciated by the Russian energy community. In early October, Alexei Alexandrovich of HRINCHENKO was awarded the prize of the contest "Energy of breakthrough". The award was presented to the scientist by RAS academician Oleg Nikolaevich FAVORSKY at a ceremony within the framework of the Russian energy week. "The low-temperature vortex method is an invention of the Russian scientific school, and the victory in the "breakthrough Energy" competition has greatly inspired our entire team to further research and improve the project," the scientist said.

A. A. TRINCHENKO, associate Professor of the Department of Nuclear and thermal power engineering at the Institute of energy and transport systems of Spbpu, together with specialists of the company "NTV-Energo" improved the concept of low-temperature vortex combustion (NTV-method), developed by the same Polytechnic, Professor Viktor Vladimirovich POMERANTSEV.

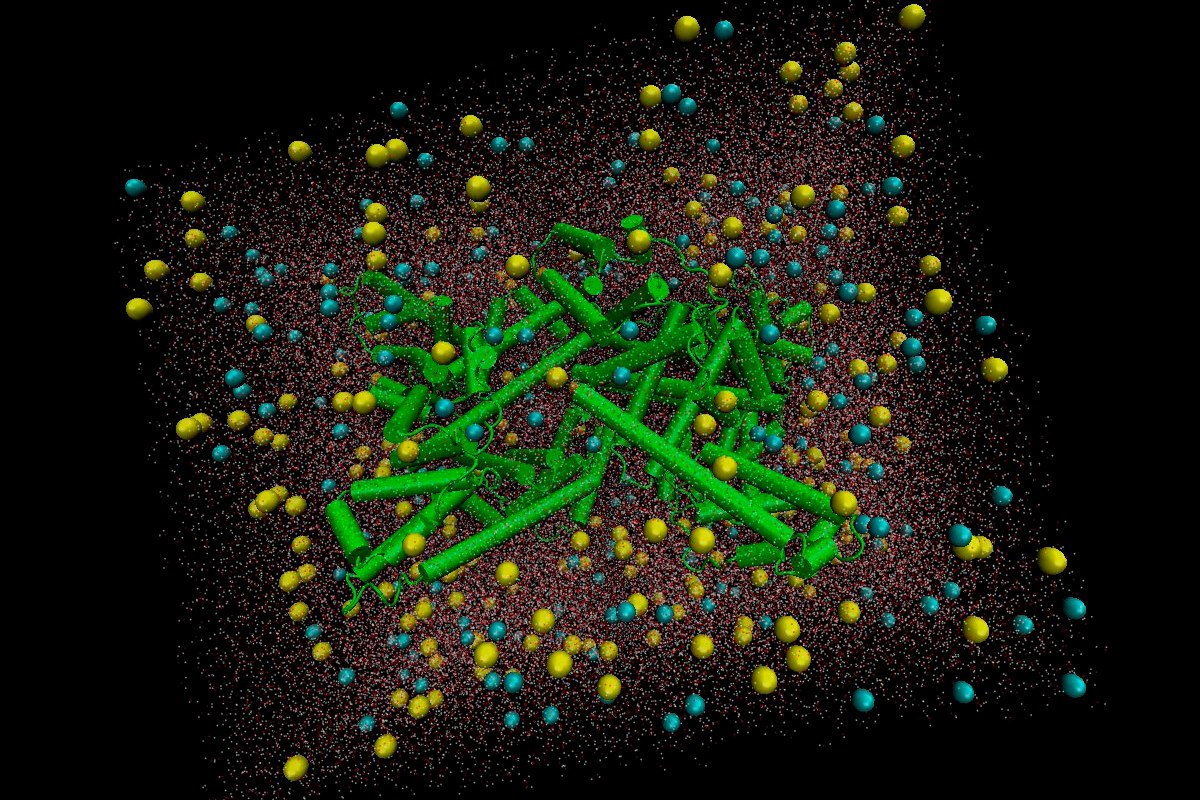

The main difference from the traditional pulverized coal torch technology is the organization of the lower vortex zone in the boiler's combustion device, in which the main mass of fuel circulates and burns. In this zone, conditions are created for a significant reduction in the generation of toxic combustion products (nitrogen oxides and sulfur oxides) due to physical and chemical processes occurring in it.

Thus, the NTV method is a technological method for protecting the environment, implemented at the stage of fuel combustion by the design of the furnace device and the operating characteristics of its operation. To date, these methods are recognized worldwide as the most promising for controlling harmful emissions from boilers, since they are ten times cheaper in comparison with cleaning of combustion products.

The developed technology can be applied to almost all solid fuels, including low-grade ones (which have large reserves in Russia and around the world), including local fuels (shale, peat, etc.). The use of the NTV method increases the efficiency of the plant to 90-93%, and the amount of nitrogen oxide emissions is reduced to 60%, and sulfur oxides-to 70%.

The obvious environmental benefits entail a significant reduction in financial costs for businesses. Energy facilities must pay taxes for environmental pollution, the amount of which depends directly on the weight of emissions. Thus, the economic effect of the introduction of the improved method at Novomoskovskaya GRES (Novomoskovsk), South thermal power station (Rubtsovsk, Altai territory), Kirov TPP-4 (Kirov), and Nazarovskaya GRES (Moscow Nazarovo, Krasnoyarsk territory), only by reducing the payment to the budget for air pollution, is more than 55 million rubles a year.

According to the scientist, there are no analogues of low-temperature vortex fuel combustion in the world. The direct foreign competitor of NTV technology is solid fuel combustion in a circulating fluidized bed (CCS), but the Russian method is simpler, cheaper and lacks the disadvantages of CCS. The introduction of the method of A. A. TRINCHENKO into the modern Russian energy system is possible both in new construction and in the reconstruction of existing equipment at energy facilities.

.jpg)